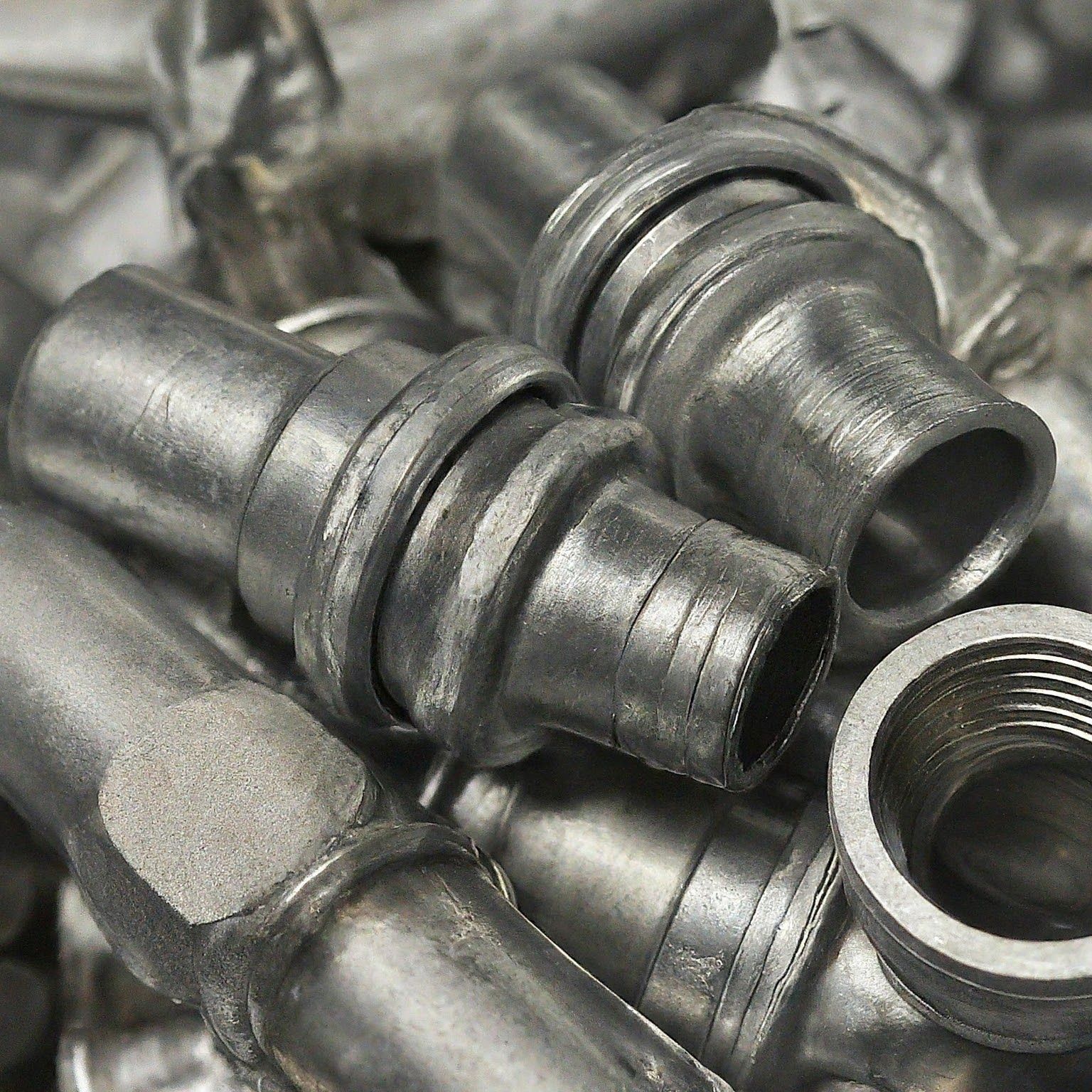

Galvanized pipe fittings have been a mainstay in plumbing for decades, valued for their affordability and durability. But are they the right choice for every project? This guide explores the advantages and limitations of galvanized pipe fittings, helping you decide when to use them and when to consider alternatives.

Galvanized pipes and fittings undergo a hot-dip process, coating them with a shielding layer of zinc. This zinc shield offers several benefits:

Zinc acts as a sacrificial layer, corroding first to protect the underlying steel from oxidation and decay. This makes galvanized fittings ideal for environments with moderate moisture exposure.

Steel offers inherent strength, making galvanized fittings suitable for handling moderate to high water pressure.

Compared to other options like copper or PEX, galvanized fittings are a budget-friendly choice.

Here at Pcfspn, we recommend galvanized pipe fittings for several applications:

The zinc coating effectively protects against corrosion in cold water lines, making them a good choice for supplying water to sinks, toilets, and washing machines.

Galvanized fittings' weather-resistant properties make them suitable for tasks like connecting sprinkler systems, building fences, or creating outdoor furniture frames (with proper sealing).

Galvanized fittings can withstand the demands of industrial environments thanks to their strength and affordability. They're commonly used in compressed air or low-pressure gas lines (check local codes).

While galvanized fittings offer advantages, there are situations where other options might be more suitable:

Over time, the zinc coating can deteriorate in hot water, potentially leading to rust flakes flaking off and contaminating the water supply. Opt for copper or PEX for hot water lines.

Highly acidic or hard water can accelerate the corrosion of the zinc coating. Consider copper or PEX for areas with problematic water conditions.

While galvanized fittings offer some corrosion resistance, they are not ideal for direct burial underground. Opt for specially coated or plastic pipes designed for underground use.

In older galvanized pipes (pre-1960s), the zinc coating may contain lead. If you suspect lead contamination, consult a professional for testing and potential replacement.

Always check local building codes, as some areas may restrict the use of galvanized fittings in specific applications.

At Pcfspn, we offer a wide selection of galvanized pipe fittings, along with other plumbing supplies to meet your project needs. Our professional staff can help you choose the right fittings for your specific application. We recommend speaking with a licensed plumber for any complex plumbing projects.

So, are galvanized pipe fittings the answer for your next project?

Consider the factors mentioned above, and if you have any questions, don't hesitate to contact Pcfspn, your trusted partner in plumbing solutions.